IR films containing anti-fog additives (drip-preventive additives) are manufactured in multifilm machines. this is done due to the unique composition of each film, where each film fulfills a different function. Studies have shown that when an IR film is installed correctly, it expedites the crop’s growth rate and yields a larger crop than a film not containing these additives.

TO achieve maximum effect from anti-fog films, the following guidelines must be taken into consideration:

The greenhouse / tunnel roof must have a minimum gradient of 15 degrees. The optimum gradient should be greater than 30 degrees. If the roof does not have the necessary gradient, the water film which forms on it will not be able to trickle sideways and will drip onto the plants.

The film must be installed shortly after purchase. If the films are not spread immediately, then they must be stored in a shaded place at a temperature which must not exceed 30 degrees. Failure to do so will shorten the life of the anti-fog films.

In structures with support cables, there may be a problem due to the cables obstructing the water droplets in their sideways trickle. In such structures, the number of cables should be kept to a minimum. The remaining cables must be installed so as not to obstruct the water droplets in their sideways trickle.

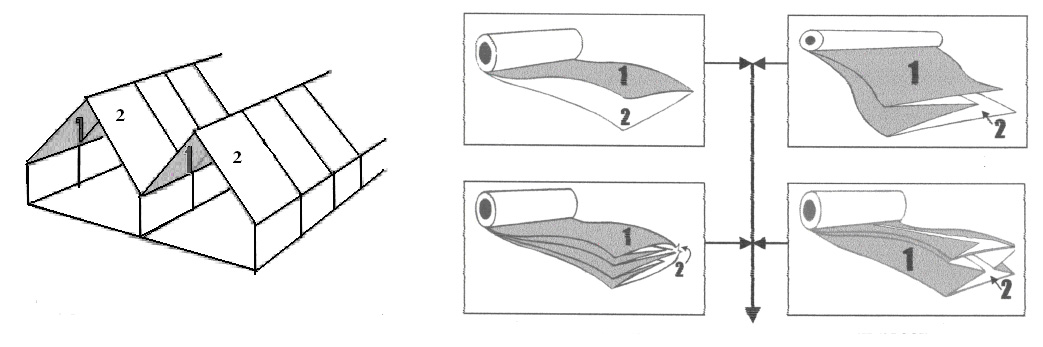

The sheets must be spread with their exterior side (Side 1) facing the plants – the inside of the greenhouse, while Side 2 must face the sky. See the figure below.