SOME FACTS ABOUT WATER

- Condensation: a process by which H2O vapors in the air are transformed from gas into liquid. Condensation occurs when warmer moist air comes in contact with cold surfaces – greenhouse film in our case.

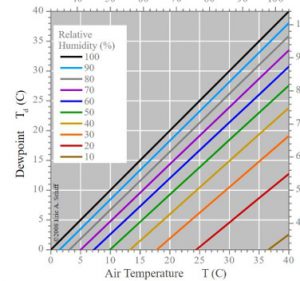

- Dew-Point: the temperature to which air must be cooled to become water vapors saturated. When further cooled, the airborne water vapors condense to form liquid water (dew). When air cools to its dew-point through contact with a colder surface, water will condense on it.

Ratio between Temp, Relative Humidity and Dew-Point

SOURCE: Institute of Agricultural Engineering

- The above table clarifies that the formation of water from vapors depends only on temperature and relative humidity.

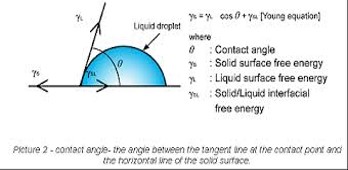

- Surface Tension defined as the tendency of liquid surfaces to shrink into the minimum surface area Surface tension is measured by dyn/cm units. The difference in surface tension between Water (72 dyn/cm) and Polyethylene (31 dyn/cm) or EVA (33dyn/cm) causes the water to form droplets. These droplets, accumulated on the film, will grow in size and eventually will fall down from the film.

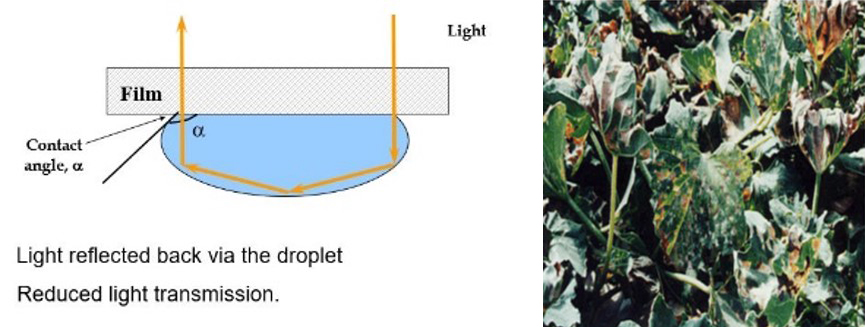

Negative effects of water droplet accumulation:

- Reducing light transmission.

- Constant dripping on the plants increases humidity and enhances leaf diseases.

- Lens effect may cause burns.

ANTI-FOG

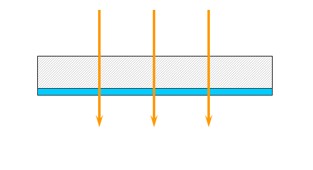

Anti-Fog – often referred as Anti-Drip – enables the film to avoid droplet creation by turn it into an even thin layer.

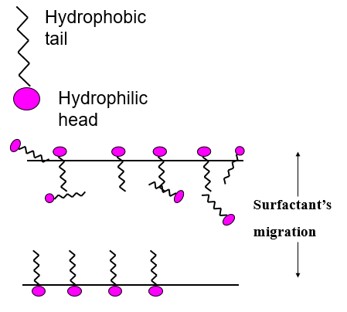

Ideal formation of water layer

In order to prevent of fog or droplet formation, Anti-Fog additives are added to the film. These additives, consist of molecules with Hydrophobic tail and Hydrophilic head, migrate to film surface, increasing surface tension; thus enables creation of a single water layer without interfering the optical properties and without Dripping.

Once there is a uniform water layer on the film, migration of Anti-Fog to the surface starts repetitively: new molecules migrate to the surface being washed by water flow and so on.

Gravity causes water layer to flow down into gutters, hence the importance to maintain an adequate slope (which explains the difficulty in having an efficient Anti-Fog effect in horizontal film installation).

Factors determine Anti-Fog lifetime:

- Using the right Anti-Fog additive according to application and climate.

- Suitable quantity of Anti-Fog in the film.

- Thickness of the film (the thicker the film is, the more Anti- Fog it can contain).

- Film structure, e.g., balance between different polymers.

Usage conditions affecting Anti-Fog lifetime:

- Extreme temperatures (high/low) film exposure.

- Greenhouse structure: efficient ventilation, height, adequate roof slope.

- Greenhouse conditions: humidity, water leaks, high evaporation from the floor (mulch).

- Crops leave surface area.

Discrete water droplets act as IR barrier and reduce cooling down of greenhouses during cold nights. Therefore the combination of Anti-Fog and IR is recommended.

ANTI-MIST

Mist in greenhouses happens due to a sudden temperature change: water vapors cooling down below dew-point forms micro-droplets.

ANTI-FOG FILMS

POLITIV offers a variety of Anti-Fog films customized for wide-range of applications: cold/hot, long/short lifetime, high/normal transparency.

All types of Anti-Fog films can be combined with other properties such as: chemical resistance, thermal IR film, Light diffusing film, cooling effect, etc.

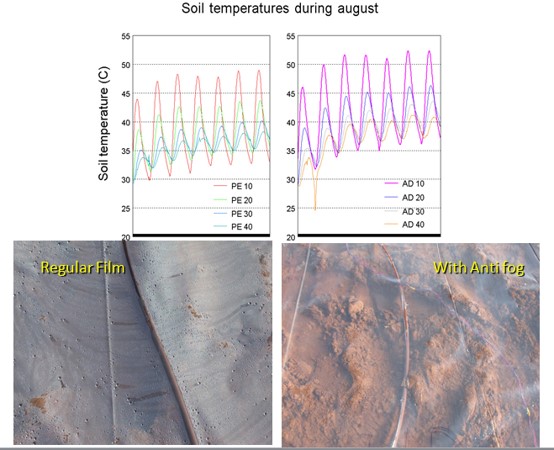

Solarization: using Anti-Fog film for solarization improves efficiency by increasing soil temperatures.

Comparison between Regular and Anti-Fog solarization film

Double-Roof: POLITIV new double-roof film containing special Anti-Fog has excellent optical properties: LT=91%, Haze= 9%. The new film helps to maintain high light transmission and thermal insulation.

POLITIV offers as well other double-roof films with light diffusion or different degree of thermicity.

Anti-Mist Film: POLITIV Anti-Mist film reduces mist formation in greenhouses even under severe conditions.

Anti-Mist should be always used with Anti Fog.

Anti-Mist may shorten life time of the Anti-Fog effect.